Universe Beauty

5D 0.07mm Premade Loose Fans Lash Extensions 500Fans

5D 0.07mm Premade Loose Fans Lash Extensions 500Fans

Couldn't load pickup availability

Shipping to

Estimated delivery on

Product Description

Product Description

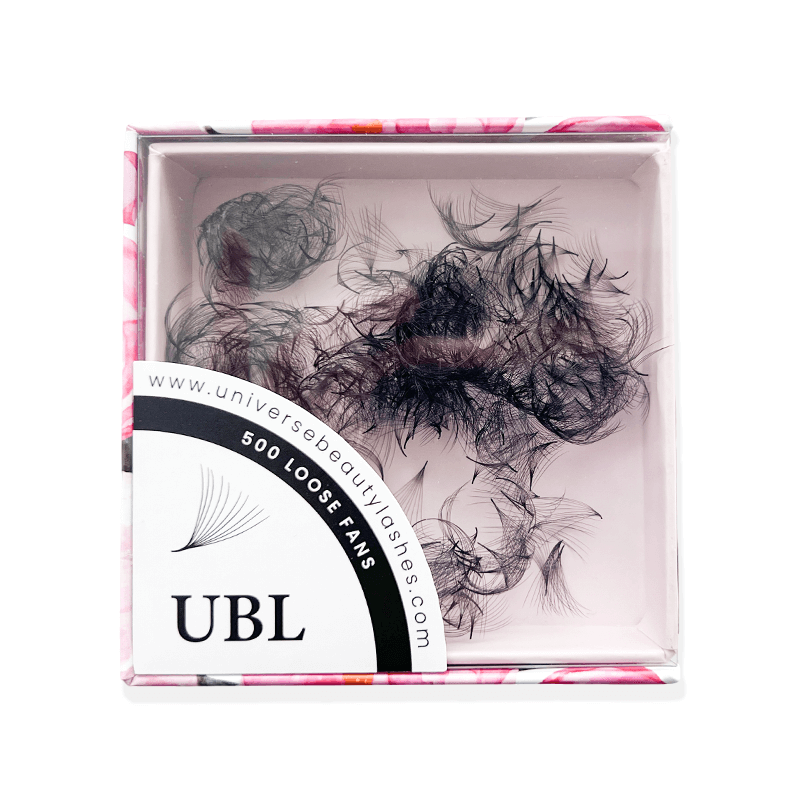

5D 0.07 Pointy Base Premade Heatbonded Loose Fans 500Fans

Features:

- 5D 0.07 Pointy Base Premade Heatbonded Loose Fans

- 500 fans per box

- Made from high-quality black PBT material sourced from Korea

- Baking technology enhances durability and softness of lash curvature

- Convenient bulk-type packaging for seamless movement and faster procedures

Benefits:

- Cost-effective solution at only 2-3 cents per fan

- Lightweight and comfortable wear

- Saves valuable time without compromising quality of work

- Creates a fluffy and natural look in half the time

- Dedicated customer service team for prompt assistance and solutions

Wholesale Inquiry

Wholesale Inquiry

Wholesale inquiries

If you are interested in purchasing eyelash extension trays in wholesale quantities (MOQ 100Trays), please contact us by email at contact@universebeautylashes.com or through whatsapp/call (+86 189 0639 0090) to get more information.

We can send up to three trays free of charge for your testing ($19.99 shipping fee), feel free to reach out and let us know which products you would like to try.

Shipping Policy

Shipping Policy

We use Fedex/DHL express shipping which normally takes around 5-7 days.